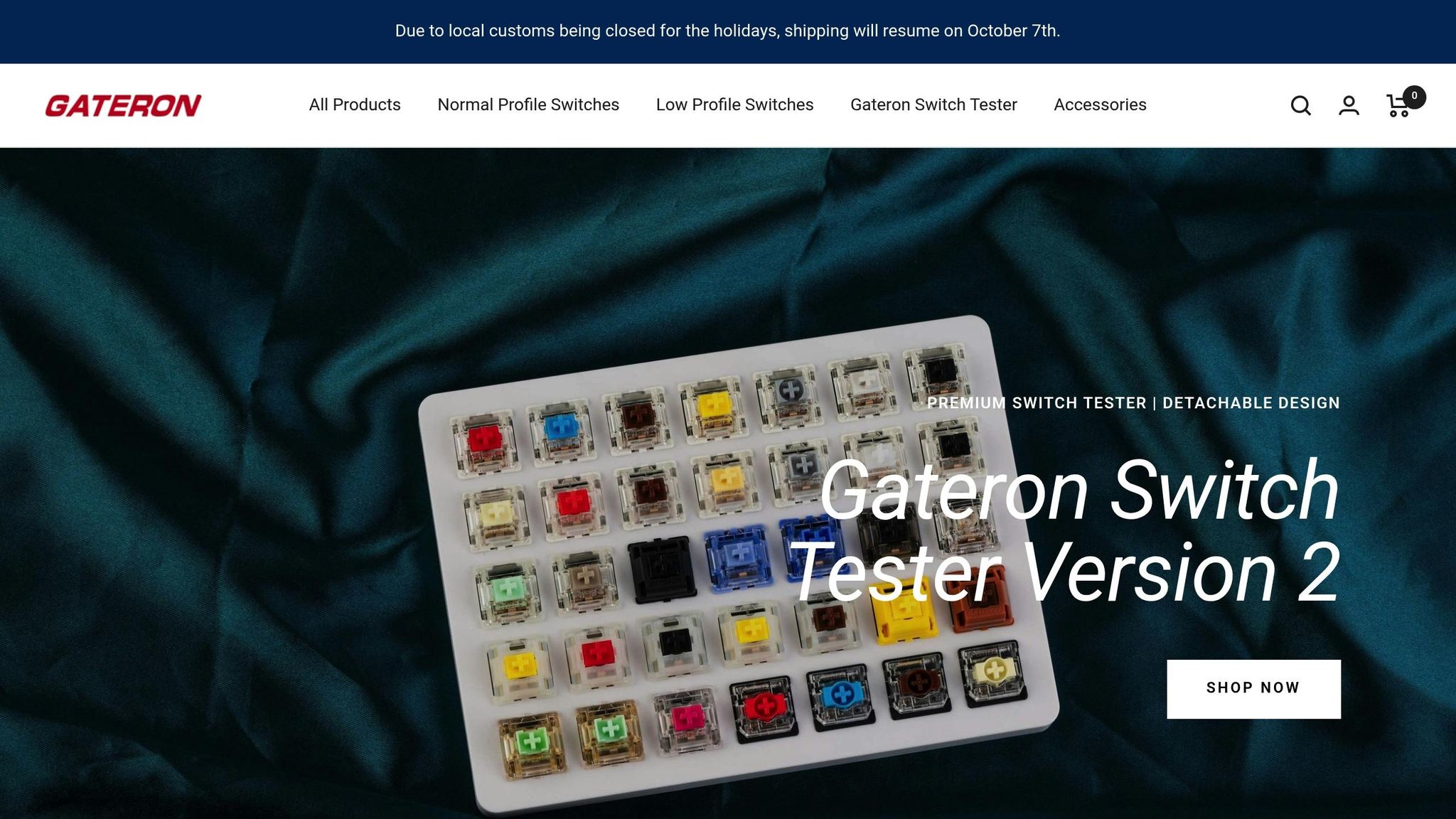

Custom mechanical keyboard switches are the backbone of a growing hobby that blends precision engineering with personal preference. These switches let users fine-tune their typing experience, offering choices in tactile feel, sound, and durability. Unlike standard keyboards, custom switches can last up to 70 million keystrokes, making them a long-term option for enthusiasts.

Here’s how they’re made:

- Design & Planning: It starts with defining features like sound profile, actuation force, and stability. Designers use CAD software for precise 3D modeling.

- Material Selection: Plastics like nylon, polycarbonate, and POM, along with metals like stainless steel, are chosen for durability and performance.

- Prototyping: Multiple iterations ensure the design meets expectations in feel, sound, and reliability.

- Manufacturing: Injection molding creates the switch components, followed by assembly and quality checks.

- Testing: Rigorous checks confirm performance, durability, and compatibility across keyboard setups.

- Customization & Packaging: Options like factory lubrication, branding, and retail-friendly packaging cater to user preferences.

With the rise of remote work and gaming, custom switches have become a way to personalize keyboards for both function and style. From concept to production, every step ensures these switches meet user demands for quality and performance.

Gateron Factory | Mechanical Keyboard at Gateron Headquarter | Learn How Gateron Switches Are Made

Concept and Design Development

Designing a custom keyboard switch begins with a clear vision. Before diving into technical specifics, designers need to identify what sets their switch apart. This initial planning phase lays the groundwork for everything else - manufacturing, performance, and the overall user experience.

Defining Key Features and Goals

The first step is deciding on the switch's standout features. One critical aspect is the sound profile, which can range from nearly silent linear switches to louder, clicky ones. Achieving the right sound involves careful choices in housing materials, internal dampening foams, and lubrication techniques.

Actuation mechanics also play a major role. The actuation point - how far a key travels before registering a press - affects responsiveness. Gamers, for example, may prefer shorter actuation points for quicker reactions. A typical setup might include 4 mm of total travel and a well-defined reset point for efficient typing. These mechanical details directly influence both tactile feedback and sound.

Switch stability is another priority. Features like the stem's rails and slider rails in the bottom housing reduce side-to-side wobble, while dustproof mounts improve overall durability.

Visual design also matters. Elements like nameplates offer branding opportunities, while LED slot placement impacts backlighting. Keycap compatibility - whether MX cross, box, or low-profile mounts - must align with existing keycap sets.

Customization is a growing trend in modern switches. Hot-swappable designs let users replace switches without soldering, and interchangeable springs and stems allow for fine-tuning. These features have transformed the mechanical keyboard space, offering users more personalization than ever before.

| Switch Type | Sound Profile | Best For | Key Benefit |

|---|---|---|---|

| Linear | Quiet to moderate | Gaming, fast typing | Smooth, uninterrupted strokes |

| Tactile | Moderate | General typing, programming | Clear feedback without a click |

| Clicky | Loud | Typing enthusiasts | Audible and tactile confirmation |

Designing with CAD Software

Once the key features are decided, designers turn to computer-aided design (CAD) software to bring their ideas to life. CAD tools allow for detailed 3D modeling of every switch component - stems, housings, springs, and contact points. These digital blueprints are essential for manufacturing and prototyping.

Precision is critical. The tight tolerances required for mechanical switches mean every measurement must be exact to ensure smooth operation and consistent performance across thousands of units. Advanced CAD systems even allow for virtual stress testing and material analysis, helping designers predict how components will hold up under repeated use. This process identifies potential weak points and optimizes component thickness for durability, saving both time and money.

The final CAD drawings include all the necessary details - tolerances, materials, finishes, and assembly instructions - bridging the gap between design and manufacturing.

Partnering with Manufacturers

With designs finalized, the next step is production. Choosing the right manufacturing partner is crucial, as not all factories can handle custom materials or unique designs.

"Most people would immediately guess that you could just find any old switch manufacturer like Gateron, Cherry, Kailh, LICHICX, Outemu, etc. and simply ask to get a custom run of switches made to x, y, and z specifications. First and foremost, this simply wouldn't work as each of these companies will have different tolerances, designs that they can and can't make, and rules when it comes to running your switches through them."

– ThereminGoat, Content Creator, Kinetic Labs

Creating custom injection molds for switch parts can cost at least $10,000 each. If the design involves three custom parts, total costs - including equipment and designer fees - can exceed $50,000 before production even begins. Complex designs often require multiple prototypes. For example, AEBoards' Naevy and Raed switches underwent at least six design iterations over nearly a year.

Production feasibility also hinges on minimum order quantities (MOQs), which typically range from 10,000 to 500,000 switches. Smaller MOQs might lower upfront costs but often come with contracts allowing manufacturers to reproduce or sell your design to others. Higher MOQs, on the other hand, ensure exclusivity.

"If you go with a lower MOQ to try and save costs in this step, you often end up with contracts that allow the manufacturers to remake your switches for other customers or sell them themselves, so you've got to give a pretty large number (or decent price per switch) if you want your switches to be strictly your own."

– ThereminGoat, Content Creator, Kinetic Labs

Strong collaboration is key to success. For example, Invokeys' Reserve switches, featuring gold flakes in their housings, required three or four prototype rounds to perfect their look. Similarly, the June 2025 partnership between Kinetic Labs and ThereminGoat for the HMX Butter Switches highlights how content creators and manufacturers can work together to navigate the challenges of production.

Prototyping and Material Selection

Once the design phase wraps up, the focus shifts to prototyping and choosing the right materials. These steps are crucial to ensure the custom switch performs well and lasts over time. By creating prototypes and carefully selecting materials, manufacturers can avoid costly mistakes during mass production.

Selecting Plastic Types for Components

The choice of plastic significantly influences a switch's sound, feel, and overall performance. Each material has unique properties that affect durability, acoustics, and the typing experience.

Nylon (PA66) is a popular choice for opaque switch housings. Known for its durability and a Young's Modulus of 2.31 GPa, nylon produces a deeper, "thocky" sound that many enthusiasts love. Its density helps create a muted tone, ideal for those who prefer a softer auditory experience.

Polycarbonate (PC) is often used for clear housings, prized for its transparency that enhances RGB lighting effects. It also creates a higher-pitched, sharper sound. As Benjamin Rudzinski from ThereminGoat's Switches explains:

"The more transparent a switch housing is, the higher pitched and clearer the sound tends to sound".

POM (Polyoxymethylene) is the go-to material for stems. With a low coefficient of friction of 0.25, it ensures smooth and consistent keystrokes. However, using POM for both stems and housings can lead to slippage unless properly lubricated.

A newer contender in the field is UHMWPE (Ultra-High Molecular Weight Polyethylene). With an incredibly low coefficient of friction at 0.1, UHMWPE reduces scratchiness and delivers an almost frictionless typing experience.

| Material | Best Use | Young's Modulus (GPa) | Coefficient of Friction | Sound Profile | Key Benefits |

|---|---|---|---|---|---|

| Nylon (PA66) | Opaque housings | 2.31 | 0.26 | Deeper, "thocky" | Durable, easy to mold |

| Polycarbonate (PC) | Clear housings | 2.2 | 0.31 | Higher pitch, clearer | Enhances RGB lighting |

| POM | Stems | 2.8 | 0.25 | Consistent | Smooth, reliable |

| UHMWPE | Stems, housings | 2.4 | 0.1 | Softer | Ultra-smooth typing |

The density of the plastic also plays a role in the sound: denser materials create a "clackier" tone, while softer ones produce a deeper sound.

It's worth noting that claims about plastic composition from vendors aren't always reliable. Benjamin Rudzinski advises:

"The only way to know for certainty the material in a switch housing is using the aforementioned, laboratory-grade results and not what the vendor tells you".

Choosing Metals for Springs and Contacts

Springs are at the heart of a switch's performance, influencing actuation force, responsiveness, and durability. The material and design of the spring determine how smoothly a key presses and rebounds.

Stainless steel is a common choice for high-quality springs. It ensures a smooth, clean press and avoids the "pinging" or "crunching" noises often associated with inferior materials.

Nickel-coated springs add an extra layer of protection against corrosion, extending the switch's lifespan even with heavy use.

Spring weight is tailored to the switch's intended use:

- Lighter springs (50–60g): Ideal for gamers who need quick actuation.

- Heavier springs (80g or more): Offer a firmer, cushioned feel for typists.

- Medium springs (60–70g): A versatile option for those who switch between gaming and typing.

Spring design also matters. Linear springs provide a consistent force throughout the keystroke, while progressive springs start light and require more force as the key travels. Slow springs demand higher initial force but maintain steady resistance thereafter.

As Emmanuel A. from Kinetic Labs puts it:

"The spring and its elasticity are what make it possible for a key to bounce back after it is pressed".

Low-quality springs, on the other hand, can lead to inconsistent key responses and unpleasant noises.

Building and Testing Prototypes

With materials selected, the next step is constructing prototypes and putting them through rigorous testing. Prototyping requires both time and money, especially for detailed designs that may need multiple iterations.

For example, AEBoards' Naevy and Raed switches went through six iterations, while Invokeys' Reserve switches required three to four rounds.

Testing is focused on both mechanical performance and user experience. Scenarios should simulate real-world use, such as extended typing sessions at varying speeds. Keeping detailed records during testing helps identify which materials produce specific sound profiles, how different spring weights affect typing comfort, and which designs hold up over time.

Costs for prototyping can be steep, often exceeding $50,000 when factoring in equipment and designer fees. However, this investment is critical. Testing reveals issues that might not be apparent during the design phase. Caitlin Goodale highlights this point:

"Things that seemed clear to us on the product team were often totally incomprehensible to real users".

This iterative process ensures the final product meets the expectations of its users.

Manufacturing Process

Once the prototyping phase is complete and materials are finalized, the production process moves into full swing. Insights gained from the prototypes are used to ensure the manufacturing process is precise, transforming designs into fully functional, production-ready parts. A key step in this phase is the injection molding process.

Injection Molding for Plastic Parts

Injection molding starts with the creation of molds, which are crafted from metal blocks - typically steel or aluminum. Each component of the switch, such as the top housing, bottom housing, and stem, requires its own specialized mold. These molds are meticulously designed to capture the fine details and unique features necessary for the components to perform as intended.

For the plastic parts, materials like ABS, PBT, POM, Nylon, or Polycarbonate are selected for their strength and performance. The process involves heating plastic pellets until they melt, injecting the molten material into the molds, and carefully packing it to prevent shrinkage. Once cooled, the molded parts are ejected from the molds.

Throughout this process, quality control ensures precise temperature regulation and timing, guaranteeing consistent and reliable components.

sbb-itb-3cb9615

Quality Control and Testing

After producing thousands of switch components, each batch undergoes strict quality control to ensure they meet the required design and performance standards. This phase is what sets professional-grade custom switches apart from lower-quality alternatives that might fail during regular use.

Checking for Physical Defects

The first step in quality control is a thorough visual inspection. Under bright lighting, trained technicians examine each molded plastic piece for common manufacturing flaws such as flash (excess plastic along mold seams), sink marks (small surface depressions caused by cooling), and warping (distortions from uneven temperatures). Any component showing these issues is immediately discarded.

Metal parts receive just as much attention. Springs are checked for proper coil tension and consistency, while contact leaves are inspected for alignment issues or damage from the stamping process. Precision tools are used to verify the dimensional accuracy of switch housings, which must fit together within tight tolerances - typically ±0.1mm. This ensures smooth stem movement and a uniform feel across all switches in a batch.

Testing Performance Metrics

Performance testing follows standardized procedures to confirm that the switches deliver on their intended design features.

- Latency testing measures the time it takes for an electrical signal to pass through a switch after it begins moving. Specialized equipment, like solenoids for consistent actuation and microcontrollers for precise timing, is used. Results are averaged from tests on five switches to account for natural variations.

- Keystroke analysis evaluates actuation force, pre-travel distance, and total travel distance using force-testing equipment. This involves pressing the switches to their bottom-out point while recording detailed force curves.

- Smoothness evaluation assesses factors like "scratchiness" by analyzing force curve noise and measuring audible noise with sensitive microphones. These metrics are combined into an overall smoothness score, weighted as 55% noise level, 15% noise frequency, and 30% scratchy factor.

Maintaining consistency across batches is critical, so testing protocols include sampling multiple units and controlling environmental factors during testing.

Durability and Compatibility Testing

In addition to immediate performance, switches must demonstrate long-term reliability and compatibility with various systems.

Durability testing is one of the most challenging aspects of quality control. Many switches are rated for 50–100 million keystrokes, but verifying these claims requires extensive fatigue testing.

"Verifying these claims requires prolonged fatigue testing. Even with a proper fatigue testing machine, it would take months to reach, say, 50 million clicks on a single keyboard's worth of switches."

- Seth Colaner, News Director, Tom's Hardware

Manufacturers use automated machines to repeatedly actuate switches, monitoring changes in feel and responsiveness over time to ensure they hold up to their durability ratings.

Compatibility testing ensures switches function properly across different keyboard layouts and PCB designs. This involves checking that switch pins align with various PCB hole patterns and maintain reliable electrical contact under different mounting conditions. It also confirms that switches fit securely with different keycap profiles and don’t interfere with keyboard cases or plates.

Manufacturers set strict tolerance standards to allow for minimal variation between switches. For instance, professional testing shows that individual switch tolerances typically have a 2% relative standard deviation, with results within 4% considered acceptable. Pre-travel distances can vary by up to ±0.25mm even within the same batch.

Finally, temperature and humidity testing ensures that switches perform consistently in different environmental conditions. This step is especially important for products shipped globally, as extreme climates can affect both plastic and metal components over time.

Customization, Packaging, and Distribution

Once switches pass quality control, they move into the final production phase, where they are tailored to meet customer specifications before being shipped across the U.S. and globally. This step transforms individual components into fully assembled, ready-to-use products, designed to cater to a variety of performance needs and aesthetic tastes.

Factory Lubing and Branding Options

For custom switch orders, many manufacturers offer factory lubrication services. This involves applying lubricants directly to key areas like the stem, housing, and spring using precision tools. The result? Smoother operation, enhanced durability, and a significant time saver for enthusiasts who would otherwise handle this process manually.

Customization doesn't stop there. Manufacturers can incorporate branding into the switches using techniques like laser etching, pad printing, or custom molding. This allows companies to add logos, product names, or unique identifiers to the switch housing without affecting performance. Some even offer the ability to customize spring weights, giving designers control over the tactile feedback of the switch. These services require specialized tools and expertise, enabling brands to create products tailored to their exact vision.

Bulk and Retail Packaging

Packaging varies depending on whether the switches are shipped in bulk or sold individually. Bulk orders are typically packed in secure trays and boxes, accompanied by the necessary documentation to ensure safe transport and proper handling.

For retail customers, the focus shifts to presentation. Clear containers or blister packs are often used to display the switches, making it easy for buyers to inspect the product. These packages also include printed specifications and compatibility details, helping consumers make informed decisions.

Role of Specialized Retailers

Once packaged, switches make their way to specialized retailers, who serve as the bridge between manufacturers and consumers. Retailers like KeebsForAll stock a wide range of custom mechanical keyboard switches, allowing customers to purchase in quantities that match their needs - whether they're testing a few options or assembling an entire keyboard.

These retailers often go the extra mile by offering switch testing stations, detailed product descriptions, and compatibility guides. Many also support group buys and provide additional services, such as extra lubrication or adjustments to spring tension, helping customers fine-tune their switches for the perfect balance of performance and personal preference.

Conclusion: From Concept to Custom Switch

Creating custom keyboard switches is a fascinating journey that combines creative vision with meticulous engineering. It starts with designers sketching out ideas in CAD software, where performance goals and technical specifications take shape. Engineers then step in, carefully selecting materials to balance durability, cost, and the desired tactile feel. The process continues with advanced manufacturing techniques like injection molding and metal stamping, followed by thorough testing to ensure each switch performs flawlessly.

Once the switches are ready, specialized retailers play a key role in bringing them to enthusiasts. Stores like KeebsForAll offer a wide range of custom switches, keycap sets, and tools, making it easy for users to experiment and personalize their keyboards. These retailers serve as the bridge between manufacturers and the growing community of keyboard enthusiasts.

This blend of precision engineering and community-driven retail has made custom switches more accessible than ever. By understanding the steps involved - from design to quality control - you can make informed choices to enhance your typing experience. Every stage of this process reflects the dedication to performance and personalization that defines the custom keyboard world. From initial sketches to the final product, each switch is a testament to innovation and craftsmanship.

FAQs

What’s the difference between linear, tactile, and clicky switches, and how do they affect typing?

When it comes to mechanical keyboard switches, the choice often boils down to personal preference and specific needs. Linear switches deliver a smooth, quiet typing experience without any tactile bump or clicking sound. This makes them a top pick for gamers or anyone who prioritizes speed and silence.

Tactile switches, on the other hand, offer a noticeable bump with each keystroke. While they remain quiet, this feedback can help improve typing accuracy, making them a favorite among typists who want a bit more interaction without the noise.

Lastly, clicky switches combine that tactile bump with a distinct click sound. They create a satisfying, engaging typing experience but are noticeably louder - something to consider if you're in a shared or quiet workspace.

To sum it up: linear switches excel in speed and silence, tactile switches strike a balance between feedback and quiet operation, and clicky switches deliver maximum feedback and sound for those who enjoy a lively typing experience.

How do manufacturers make custom keyboard switches durable and reliable?

Manufacturers prioritize the durability and reliability of custom keyboard switches by utilizing top-tier materials such as sturdy plastics and metal contacts. These components are chosen specifically to handle the demands of frequent use and maintain their integrity over time.

To ensure lasting performance, these switches undergo rigorous testing, designed to simulate tens of millions of keystrokes. In fact, some high-end switches are rated to endure up to 100 million presses. This thorough testing guarantees that each switch remains responsive and maintains its tactile feel, even after years of heavy typing or gaming.

What factors should you consider when choosing materials for custom keyboard switches, and how do they impact performance and sound?

When picking materials for custom keyboard switches, three things matter most: durability, sound profile, and tactile performance. For example, nylon stands out for being tough and delivering a deeper, more muted sound, while polycarbonate leans toward a sharper, higher-pitched tone. On the other hand, housing materials like POM, nylon, or UHMWPE can significantly influence both the typing feel and the sound.

The material you choose doesn’t just affect how the keyboard sounds - it also impacts how the switches respond as you type. Rigid materials like aluminum or steel, for instance, tend to enhance high-frequency tones, resulting in a crisp, clicky sound. These choices are key to customizing your typing experience, whether you prefer a quieter, smoother feel or a more pronounced, responsive feedback.

![[Pre-Order] Autumn Leaves PBT Keycaps - KeebsForAll](http://keebsforall.com/cdn/shop/products/DSC09732.jpg?v=1676148273)

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.