Solder joint defects are a leading cause of problems in mechanical keyboard PCBs. They can result in unresponsive keys, erratic behavior, or complete failures, often due to poor soldering techniques, material quality, or design flaws. Common issues include:

- Cold solder joints: Caused by insufficient heat, leading to weak connections.

- Solder bridges: Excess solder creates unintended electrical connections.

- Voids: Gas pockets weaken joint strength and conductivity.

- Solder balling: Loose solder spheres may cause shorts or reliability issues.

Preventing these defects requires proper design, precise temperature control during soldering, and high-quality materials. Regular inspections, such as X-rays, help catch hidden flaws early. For enthusiasts and manufacturers alike, addressing these issues ensures durable, reliable keyboards that perform consistently over time.

Say No To Soldering Defects | PCB Knowledge

Common Solder Joint Defects

Understanding the visual characteristics of solder joint defects is crucial for identifying and resolving performance issues in PCB assemblies. Each defect has unique traits that can compromise the reliability and functionality of the circuit. Below, we break down the most common solder joint defects, their appearance, causes, and how they impact PCB performance.

Cold Solder Joints

Cold solder joints happen when the soldering process doesn’t apply enough heat, leaving the solder partially melted and failing to bond properly with the pad and component lead. These joints are easy to spot due to their dull, grainy, or crystalline appearance, lacking the smooth and shiny finish of a proper connection. The result? High-resistance connections that can cause intermittent failures or even complete circuit malfunctions. What makes them particularly tricky is that they can often pass initial visual inspections, posing a hidden risk to the overall reliability of the assembly.

Solder Bridges

Solder bridges occur when excess solder flows between adjacent pads or traces during reflow, creating unintended electrical connections. This issue often stems from too much solder paste, poor stencil design, or inadequate spacing between pads. The consequences can be severe - short circuits that disrupt intended paths, damage components, or interfere with signals. In high-density designs, especially those with fine-pitch components, solder bridges can cause multiple faults at once, making troubleshooting a nightmare. Bridges in areas with higher voltage or current levels can be even more dangerous, amplifying the risks.

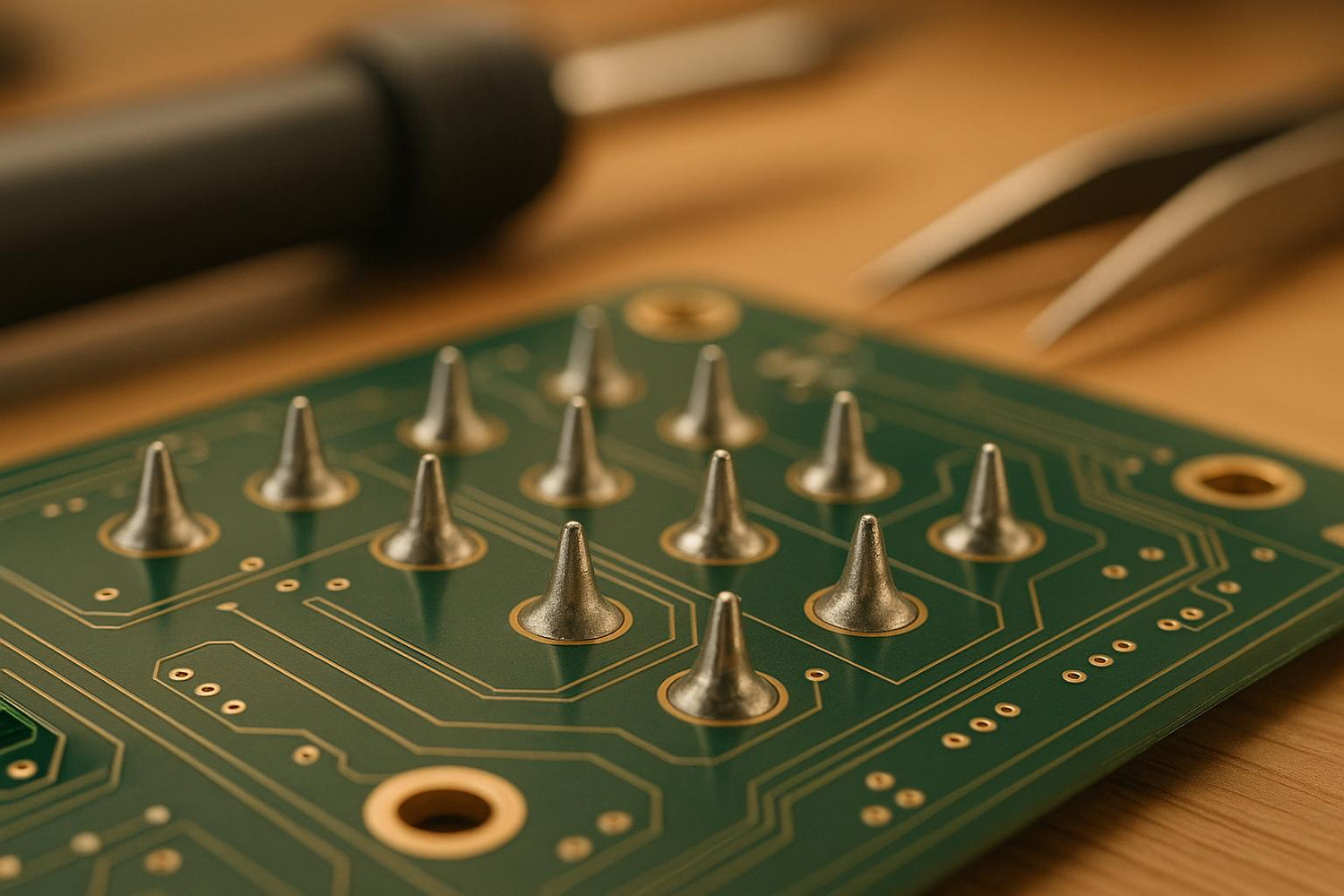

Voids and Solder Balling

Voids are gas pockets trapped inside solder joints during the reflow process. They typically form due to solder paste outgassing, improper reflow temperature profiles, or surface contamination. These voids are often invisible without X-ray inspection and result from rapid temperature increases or insufficient peak temperatures. The presence of voids reduces the effective solder volume, creating weak points that compromise both the mechanical strength and electrical conductivity of the joint. Even relatively small voids - occupying 20–30% of the joint volume - can drastically reduce the joint’s fatigue life and reliability.

Solder balling, on the other hand, refers to small, unattached solder spheres that form on the PCB surface during reflow soldering. This defect is often caused by poor solder paste quality (e.g., high slump or low metal content), contamination, or poorly optimized reflow conditions. These solder balls tend to appear around component leads or underneath components, where they can inadvertently create conductive paths or shorts. While a single solder ball might not cause immediate failure, its presence indicates deeper process issues that could undermine long-term reliability.

| Defect Type | Visual Appearance | Primary Cause | Performance Impact |

|---|---|---|---|

| Cold Solder Joints | Dull, grainy, or crystalline surface | Insufficient heat during soldering | High-resistance connections; intermittent failures |

| Solder Bridges | Visible solder linking adjacent pads | Excess solder flow or poor stencil design | Short circuits; circuit malfunction |

| Voids | Gas pockets (visible via X-ray) | Solder paste outgassing; improper reflow | Reduced solder volume; weakened joint integrity |

| Solder Balling | Small, separated solder spheres | Poor solder paste quality; bad reflow setup | Unintended connections; potential for shorts |

What Causes Solder Joint Defects

Solder joint defects can stem from issues related to temperature control, material quality, PCB design, and process management. Pinpointing these causes is key to preventing problems that could compromise PCB assemblies.

Incorrect Temperature and Reflow Settings

One of the main culprits behind solder joint defects is improper management of reflow temperatures. If the reflow profile doesn’t hit the correct peak temperature, you risk cold joints, voids, and poor wetting, all of which lead to incomplete connections. On the flip side, too much heat can cause thermal stress, lifting pads or damaging sensitive components.

Reflow must be carefully controlled through all phases - preheat (150–180°C/302–356°F), soak (150–200°C/302–392°F), peak (235–245°C/455–473°F), and cooling (2–4°C/3.6–7.2°F per second). Sudden cooling or rapid temperature changes can trap gases inside the solder, creating voids and internal stresses that weaken the joints. These temperature mishaps often show up as cold joints or voids, which are common defects.

Ball Grid Array (BGA) components are particularly tricky. Their complex thermal masses make them vulnerable to rapid temperature changes, which can cause outgassing, or to insufficient peak temperatures, which prevent proper wetting.

Material and Design Problems

Even if the reflow process is well-executed, poor material quality or flawed PCB design can still lead to defects.

Solder paste quality plays a critical role. If the paste has high slump, it can flow too much, leading to bridges or icicles. On the other hand, low metal content in the paste can result in insufficient solder volume, causing open joints or dewetting. Proper storage of solder paste at recommended temperatures (typically 35.6–50°F or 2–10°C) and ensuring clean surfaces are crucial to avoid voids and poor wetting. For moisture-sensitive components, especially BGAs, absorbed moisture can cause severe voiding.

PCB design flaws also contribute to defects. If there’s insufficient thermal relief around pads, uneven heating during reflow can cause tombstoning (where a component tilts and stands on one end) or distortion. Small pad sizes or improper pad spacing are another common issue. Pads placed too close together can cause solder bridges, while pads that are too small may not hold enough solder for a reliable connection.

| Material/Design Issue | Specific Problem | Resulting Defect |

|---|---|---|

| High slump solder paste | Excessive material flow | Bridges, icicles |

| Low metal content paste | Insufficient solder volume | Open joints, dewetting |

| Contaminated paste | Oils, oxides, or chemicals | Dewetting, voids, icicles |

| Surface contamination | Dust, grease, or residues | Poor wetting, voids |

| Insufficient thermal relief | Uneven heating | Tombstoning, distortion |

| Improper pad spacing | Pads too close together | Solder bridges |

| Inadequate pad sizing | Not enough solder volume | Open joints, poor connections |

Even with the right materials and design, human error can still undermine these efforts.

Human Error and Process Control

Operator mistakes and weak process controls are frequent contributors to solder joint failures.

For example, poor tip maintenance or failing to clean PCBs properly can introduce contaminants that lead to solder failures. Misaligned stencils or improper solder paste application can result in uneven solder volumes - too much paste causes bridges and icicles, while too little leads to open joints and dewetting.

Maintaining the right reflow oven temperatures is equally critical. Solder has a narrow melting range, so consistent temperature control is non-negotiable. Regular calibration of equipment ensures uniformity, but this step is sometimes skipped due to tight production schedules.

Component misalignment during reflow can cause defects like tombstoning, distortion, or disturbed joints - all of which may lead to eventual failure. Tombstoning often occurs due to uneven solder paste application or thermal imbalances. Even slight movement during the cooling phase can disrupt the solidification process, weakening the joint.

Mechanical shock during assembly is another risk. Excessive force during mounting or accidental drops can introduce stress that exceeds the solder joint’s limits, leading to fractures. While these joints may look fine initially, they’re prone to failure under regular use. Additionally, any residual soldering flux left on the board can increase insulation resistance and heighten the risk of corrosion.

To address these challenges, operators should be trained in proper handling and storage practices. Periodic X-ray inspections can help detect voids early, and working closely with material suppliers ensures the use of low-void solder pastes tailored for specific needs. Reliable equipment, skilled personnel, and strong quality management systems are the backbone of robust process control.

sbb-itb-3cb9615

How to Prevent Solder Joint Defects

Preventing solder joint defects means paying close attention to three key areas: PCB and stencil design, reflow process settings, and material handling. Each of these plays a unique role in ensuring reliable solder connections that can handle the mechanical and thermal demands of keyboards.

PCB and Stencil Design

A well-thought-out PCB design is essential for avoiding issues like insufficient solder volume or bridging. Pads need to be properly sized and spaced to ensure solder doesn’t flow between them during the reflow process.

Thermal management is another critical aspect. Features like thermal reliefs and strategically placed vias help distribute heat evenly, reducing the risk of components tilting or standing on end (a defect known as tombstoning). This becomes especially important in keyboard PCBs with high component density.

For Ball Grid Array (BGA) components, often found in keyboard controllers, specific design considerations are necessary. Via-in-pad designs need proper plugging or capping to prevent trapped air during reflow, which can create voids inside solder joints. These voids weaken the connection and can lead to failures under the constant mechanical stress of typing.

Stencil design also plays a big role in achieving uniform solder paste application. The stencil’s thickness and aperture sizes must match the pad and component dimensions perfectly. Laser-cut stencils offer the precision needed for consistent paste deposition - especially important for keyboards with numerous switch solder joints that require identical treatment.

By optimizing these design elements, you set the foundation for a well-controlled reflow process.

Reflow Process Settings

The reflow process has four distinct phases, and each one is crucial for preventing defects. Fine-tuning these phases ensures high-quality solder joints.

- Preheat phase: Gradually raises the board temperature to 302–356°F (150–180°C) over 60–90 seconds. This activates the flux and minimizes rapid outgassing, which can create voids.

- Soak phase: Holds the temperature steady between 302–392°F (150–200°C) for 60–120 seconds. This allows trapped gases to escape before the solder melts.

- Peak phase: Brings the temperature to 455–473°F (235–245°C) for 20–40 seconds, depending on the solder alloy. This ensures the solder melts completely and wets properly without overheating, which can lead to defects like solder balling or damage to components. BGA components are particularly sensitive during this phase, as improper temperatures can cause outgassing or incomplete wetting.

- Cooling phase: Reduces the temperature at a controlled rate of 3.6–7.2°F per second (2–4°C per second). Cooling too quickly can introduce thermal stress and crack solder joints, while cooling too slowly can unnecessarily extend production time.

Regular calibration of reflow ovens is essential to maintain accurate temperature profiles across the entire PCB surface. Variations in temperature can result in uneven solder melting and inconsistent joint quality. For high-volume production, sticking to a calibration schedule helps avoid gradual quality degradation.

Using a nitrogen atmosphere during reflow can further improve wetting and reduce oxidation. While it adds complexity and cost, this method is often worth it for high-end mechanical keyboard PCBs where durability is a priority.

Material Selection and Storage

The materials used in soldering are just as important as the design and process settings. High-quality solder paste is critical. Paste with low metal content, contamination, or high slump can lead to defects like solder balling, spattering, and bridging. Opting for low-voiding flux formulations helps minimize outgassing and void formation during reflow.

Storage conditions play a major role in maintaining material quality. Solder paste should be stored at 35.6–50°F (2–10°C) and allowed to reach room temperature before use. Using cold paste straight from the refrigerator can cause moisture to condense on its surface, which vaporizes during reflow and creates voids.

Moisture is a common culprit behind solder joint voids. To address this, PCBs and moisture-sensitive components should be baked at 212–257°F (100–125°C) for 4–8 hours before assembly to remove absorbed moisture. This step is especially important in humid environments or during summer months when ambient humidity is higher.

Cleanliness is another factor that can’t be overlooked. Contaminants like dust, grease, or oxidation on PCB pads or component leads can interfere with solder wetting, leading to gaps or voids. Ensuring boards and components are clean before assembly and controlling humidity levels in the production area can prevent these issues.

Collaborating with material suppliers is also valuable. Testing different low-voiding solder pastes on sample boards before committing to production ensures the chosen paste performs well with the specific PCB design and components. This proactive approach can save significant time and costs by avoiding potential quality problems later.

Finally, proper training for operators on handling and storage practices is crucial. Even the best materials and equipment can’t compensate for poor handling that introduces contaminants or damages components before they reach the reflow oven.

Inspection and Quality Control Methods

Once defect prevention measures are in place, it’s essential to confirm their effectiveness. Inspection and quality control methods play a key role in catching problems before they impact customers or result in costly field failures.

X-Ray and Visual Inspection

X-ray inspection is a powerful tool for uncovering hidden defects, especially in components like Ball Grid Arrays (BGAs), where solder balls are concealed beneath the component. This imaging technique helps manufacturers spot issues such as voids, trapped gases, and incomplete solder wetting within solder joints. By conducting periodic X-ray checks on sample boards, manufacturers can identify potential defect trends early and address them before they escalate.

Visual inspection complements X-rays by focusing on surface-level defects. Inspectors can identify problems like tombstoning (components standing upright due to uneven solder melting), solder bridges (unintended connections between adjacent pads), cold joints (dull, grainy solder indicating incomplete melting), and solder balling (tiny solder spheres separated from joints). Additionally, visual checks can reveal component misalignment, pad lifting, and residual flux contamination, which often indicate issues with process control. While visual inspection doesn’t uncover subsurface defects, its speed and simplicity - especially with proper lighting and magnification - make it a practical method for providing immediate feedback. This approach reduces warranty claims and enhances product reliability.

Together, these methods create an essential link between defect prevention and ongoing quality assurance.

Regular Testing and Sampling

Beyond immediate inspections, regular testing and sampling ensure continuous validation of manufacturing processes. By analyzing representative samples, manufacturers can establish defect rate baselines. Systematic data collection - tracking defect types, locations, frequencies, and their relationship to process parameters - enables effective root cause analysis. For instance, if X-ray inspections repeatedly show voids in specific areas or when using certain solder paste batches, manufacturers can take corrective steps, such as adjusting reflow profiles, revising PCB designs, or evaluating material quality.

Trending inspection data over time also helps detect process drift, allowing manufacturers to address issues proactively rather than reacting to customer complaints or field failures. This approach not only saves costs but also improves overall reliability. Inspections should be strategically timed after process changes, material supplier updates, or new reflow profiles are introduced. This ensures that any shifts in manufacturing parameters are closely monitored and correlated with defect rates.

To support this quality control strategy, equipment calibration and operator training are critical. Regular calibration of X-ray machines and reflow ovens ensures consistent and accurate defect detection, while well-trained operators can effectively use inspection tools, interpret findings, and document results.

Material quality also plays a significant role. Manufacturers should verify that solder paste formulations are designed to minimize voiding by reducing outgassing during reflow. Testing solder paste for key parameters like viscosity, metal content, and flux activity ensures batch-to-batch consistency. Problems such as high slump, low metal content, or contamination can lead to defects like solder balling, spatter, and bridging. Partnering with material suppliers to validate low-voiding solder pastes for specific applications helps ensure reliable assembly processes and consistent product quality.

Conclusion

Mechanical keyboard PCBs face repeated stresses from keystrokes, extended use, and shipping conditions, which can lead to solder joint failures. However, these issues can often be avoided with a clear understanding of the problem and the application of effective quality control measures .

Preventing these failures involves a well-rounded approach that includes careful material selection, process refinement, thoughtful design, and thorough inspection protocols. For instance, optimizing reflow processes and design can eliminate many defects. Using low-voiding solder paste, storing it at temperatures between 35–50°F, and pre-baking PCBs at 212–257°F for 4–8 hours can significantly reduce void formation. These steps, when combined with robust design and material management, ensure a more reliable and durable product.

For enthusiasts at KeebsForAll, these quality control measures are key to delivering keyboards that perform flawlessly with every keystroke. Reliable solder joints are essential for maintaining consistent electrical connections across the keyboard matrix. Given the specialized nature of custom keyboards, field failures are not just expensive to fix - they can also damage customer trust in premium products. Incorporating inspection protocols like periodic X-ray scans for hidden voids in BGA components and visual checks for surface defects helps identify and address potential issues before the keyboards reach users .

Addressing these interconnected challenges requires a comprehensive strategy that covers design, material handling, process control, and regular testing. By integrating these quality assurance practices, manufacturers can ensure durable keyboards that meet customer expectations. These preventive measures not only enhance product reliability but also reduce post-production costs by improving first-pass yields and delivering keyboards built to last.

FAQs

How can I prevent solder joint defects when assembling PCBs for mechanical keyboards?

Preventing solder joint defects during PCB assembly demands careful attention and the right techniques. Here are some essential practices to keep in mind:

- Choose quality materials: Always opt for reliable solder, flux, and PCB components. High-grade materials can minimize the chances of defects.

- Monitor temperature settings: Keep your soldering iron at the proper temperature - typically between 350°F and 400°F. Too much heat can damage components, while too little may result in poor solder flow.

- Ensure clean surfaces: Make sure to clean PCB pads and components thoroughly to remove dirt, grease, or oxidation. A clean surface helps create stronger, more durable bonds.

- Use the correct solder amount: Applying too much or too little solder can weaken joints. Aim for just the right amount to ensure a solid connection.

By sticking to these guidelines, you’ll greatly reduce the risk of soldering issues and improve the reliability of your mechanical keyboards. For enthusiasts looking to upgrade their builds, stores like KeebsForAll offer premium components to help achieve excellent results.

How does solder paste quality affect defects like solder balling and voids in PCB assembly?

The quality of solder paste is key to avoiding defects like solder balling and voids during PCB assembly. If the solder paste is subpar, it can result in uneven melting, inconsistent spreading, or weak bonding, all of which increase the chances of assembly issues.

To reduce these risks, it’s important to choose high-quality solder paste with the right composition and viscosity for your specific needs. Additionally, proper storage and handling - such as maintaining the recommended temperature and preventing contamination - are crucial for preserving its effectiveness. These practices can greatly enhance the reliability of solder joints and the overall quality of your assembly process.

Why is precise temperature control important during the reflow process for reliable PCB solder joints?

Precise temperature management during the reflow process is crucial for creating strong, dependable solder joints in PCB assembly. If the temperature falls short, the solder might not fully melt, leading to weak or incomplete connections. On the other hand, overheating can harm components or result in issues like solder balling or bridging.

Keeping the right temperature profile ensures the solder properly adheres to both the PCB pads and the component leads, forming a stable and lasting bond. Regular monitoring and calibration of reflow ovens play a key role in minimizing defects and enhancing the overall quality of the assembly.

![[Pre-Order] Autumn Leaves PBT Keycaps - KeebsForAll](http://keebsforall.com/cdn/shop/products/DSC09732.jpg?v=1676148273)

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.